Who We Are

Our journey as the Best Fiberglass Manufacturer in the UAE and began in 2007 so we launched as “Leadergrate” and right in the bustling heart of Dubai. So from the very beginning, we aimed to set new benchmarks because providing top-notch fiberglass solutions tailored to the region’s dynamic commercial and industrial construction sectors.

Fast forward to 2013 and fueled by the UAE’s unyielding spirit of innovation and we made a significant leap by opening a state-of-the-art and manufacturing facility in Sharjah. In the strategic decision positioned us right in the middle of the UAE’s because growing aquaculture market and allowing us to create world-class fiberglass products that meet the unique demands of the nation.

Early partnerships with some of the country’s most esteemed salmon fish farms further cemented our reputation as the Best Fiberglass Manufacturer in the UAE. These achievements opened up new opportunities and so leading us into the water and wastewater industries and establishing as a reliable partner in the GCC’s crucial desalination sector.

Today, our diverse portfolio includes a wide range of GFRP vessels and structural components and catering to industries as varied as airports, transportation, energy, marine, infrastructure, hospitality, and architecture. But innovative spirit has also taken us into the exciting worlds of theming and water park entertainment, because We use advanced design and manufacturing skills to bring imaginative concepts to life.

When local options don’t quite meet the mark and discerning clients consistently turn to us as the best fiberglass manufacturer in the UAE because valuing our expertise over imported products from North America and Europe. We take great pride in serving a distinguished international clientele and delivering complex engineering solutions and executing highly specialized projects with unparalleled precision and excellence.

Our Vision

To be the preferred partner in high performance fiberglass solutions across the GCC and beyond, recognized for quality, precision, and innovation.

Our Mission

Deliver superior grade fiberglass products and that meet international standards. Because Provided tailored manufacturing services for industrial, infrastructure, and commercial needs. Commit to sustainable, safe, and durable production practices.

Our Process

Engineering capabilities

concept design

We extend our assistance to clients and consultants in developing concept designs during the project engineering phase.

BIM engineering

Our Design team is experienced in BIM modelling and proficient in using Revit, CATIA, and SolidWorks software.

FEM stress Analysis

Autocad 2D & 3D design

method of manufacturing in UAE

OPEN MOULD SYSTEM - CURING AT AMBIENT TEMPERATURE

The plug is made from fiberglass material as the process involves manually applying resin on each layer of fiberglass and mat until the required thickness is achieved. Because Curing occurs at ambient temperature. This method uses steel rollers to eliminate and entrapped air inside the laminates, resulting in a glass content between 30–40%. And to enhance the quality of the laminate because skilled technicians use steel rollers throughout the process to carefully remove any entrapped air between the layers. offering excellent mechanical properties and dimensional stability.

OPEN MOULD SYSTEM - POST HEATED MACHINERY

Machine is cleaned and then the technicians start weaving because the direct fiber roving between steel blocks while resin is poured in a specific quantity. This process involves manual pressing to achieve a glass content of 30-40%. So the thickness is achieved and the heating process starts for 40 minutes. And then, chilled water is used internally to cool down the product and allow for quick release of the product.The result is a high quality, precision and formed composite part with excellent surface finish durability,and performance ready for deployment .

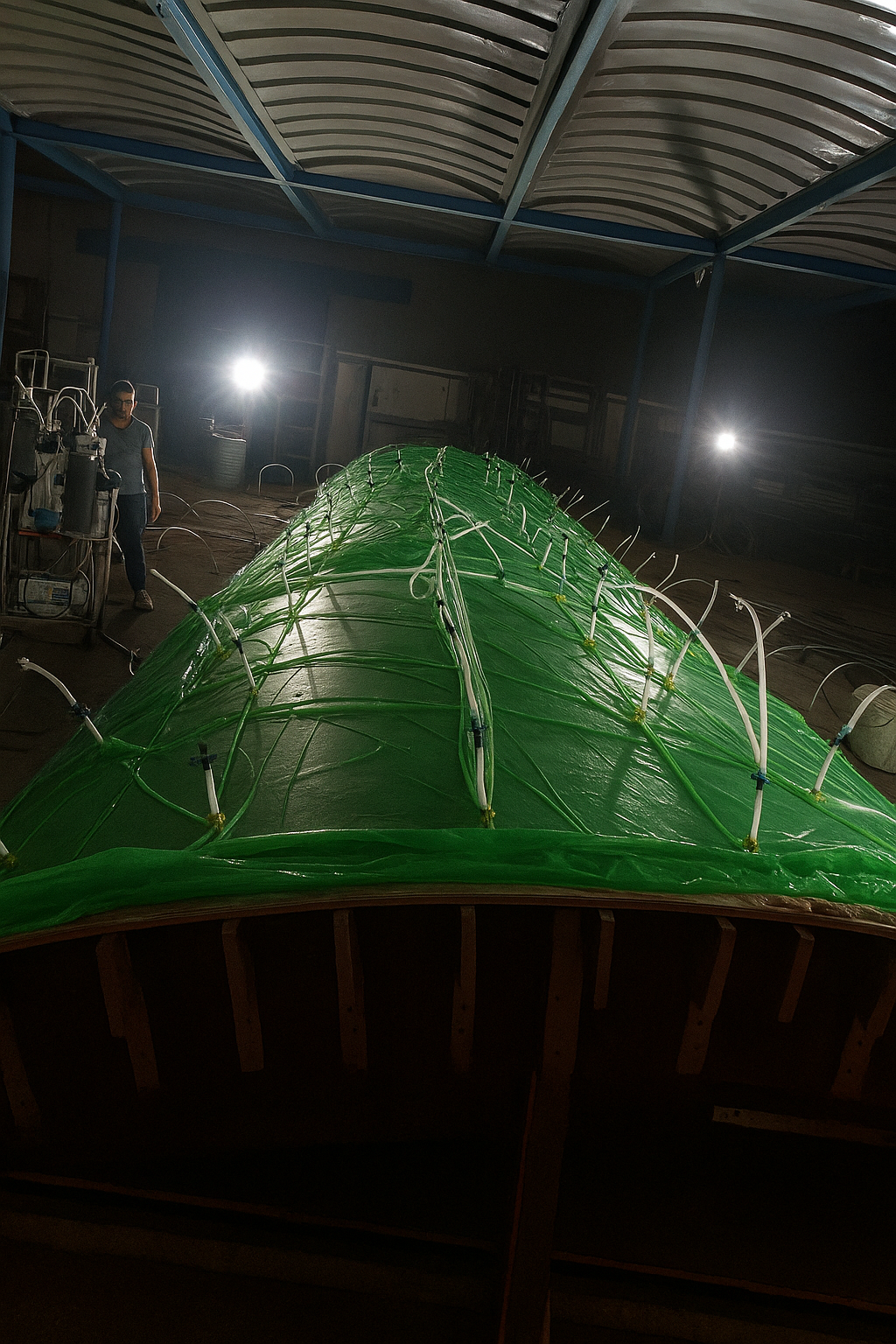

VACUUM INFUSION PROCESS ( VIP )

Vacuum Infusion Process (VIP) uses vacuum pressure to drive resin into a laminate. Because dry materials are laid into the mold, and the vacuum is applied before the resin is introduced. So Resin is sucked into the laminate via tubing once a complete vacuum is achieved. So VIP creates a laminate with high fiber content (up to 70% fibers by weight), resulting in a strong, stiff, and lightweight part. And results in parts that are significantly stronger, stiffer, and lighter compared to those made using traditional open-mold methods.

testing & certification

In house testing

Carry out in-houses the basic testing required on laminate, such as resin viscosity, loss on ignition, Barcol hardness, and thickness.

third party lab testing

Collaborates with local laboratories in the UAE and the USA for testing our products, including fire tests, fire integrity tests, thermal properties and mechanical properties etc.

product certification

Use international certifying bodies such as UL or Intertek to certify our products, including UL 1316 and UL 10C.

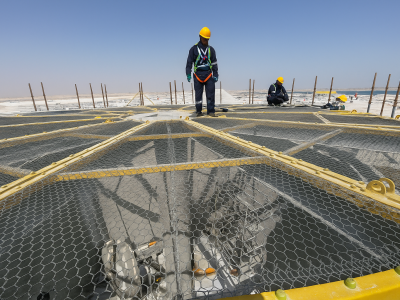

Site services in UAE & GCC

Site survey within UAE & GCC

Our supervisor is deployed to visit the site for taking measurements or assessing site conditions in the event of any maintenance-related work.

Site supervision within GCC countries

We Provided training for our clients to install our product, with a supervisor serving abroad for the duration of installation and testing at the site.

Site installation within UAE

We provided Site installation can provide 2 to 3 installation crews to install our products at projects in the UAE. Because our team is highly HSE trained for working on any site and including airports, sewage plants, power plants, onshore, and offshore locations.

Our Products

Our Certifications

At Al Mustaqbal, we pride ourselves on our commitment because excellence and ongoing professional development. So our team holds a diverse array of certifications and ensuring that we deliver the highest quality of service to our clients. Here are some of the certifications our team members have achieved.

Our Clients

At Al Mustaqbal, our clients are at the heart of everything we do. Because we are proud to have partnered with a diverse range of businesses, organizations, and individuals who have entrusted us with their needs. From startups to established enterprises, our commitment to delivering excellence remains unwavering.

Message from our ceo

Through our long expertise and engineering background, team is committed to providing the best solutions to customers because searching for reliable products with a 30-year design life. Humble beginnings, we keep achieving great success in the market of the Middle East and North Africa. In engineering team are equipped with the best design tools because collaborates with our clients and end-users to introduce composite materials in the construction industry and challenging the long and traditional use of metal in harsh corrosive environments and strict safety requirements.

So we are pioneers in providing high-strength products because made from lightweight and composite materials in the offshore market. Team has gained an international reputation and its design capabilities and the quality of the final products. Over the last few years, our team has developed innovative solutions and especially in the offshore and marine market. So we are proud of our accomplishments and work hard to bring the composite business to a new level in the Middle East.

And we take immense pride in our achievements and remain committed to pushing the boundaries of composite technology. Because our goal is to lead the transformation of the construction and marine sectors. But offering sustainable, corrosion-resistant and alternatives that outperform traditional materials . So the elevating the composite industry to new heights across the MENA region and beyond.