In the fast-paced world of construction and infrastructure, the need for materials that combine strength, durability, and sustainability is at an all-time high. As the UAE steps up as a leader in architectural innovation and large scale infrastructure projects, a game-changing material is making waves: Glass Fiber Reinforced Polymer (GFRP). For developers, contractors, and architects looking to gain a competitive advantage, teaming up with a top GFRP manufacturing company in the UAE has become a crucial strategy.

Introduction: The Evolving Landscape of Infrastructure

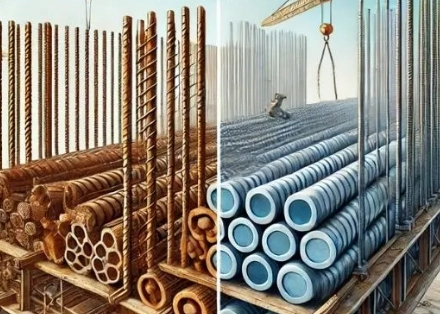

For ages, traditional construction materials like steel, concrete, and timber have been the foundation of infrastructure development. But as projects grow bolder and environmental challenges become more pressing especially in the tough climate of the UAE these materials start to show their weaknesses. Issues like corrosion, high maintenance costs, and environmental impact are just a few of the ongoing hurdles.

This is where GFRP comes into play: a composite material that’s not only transforming the way we build infrastructure but also raising the bar for performance, efficiency, and sustainability.

What Is GFRP?

Glass Fiber Reinforced Polymer (GFRP) is a composite material crafted from a polymer matrix that’s reinforced with glass fibers. This unique blend creates a product that’s lightweight, strong, non corrosive, and incredibly durable. GFRP is manufactured through cutting-edge processes by specialized companies, many of which are flourishing in the UAE.

The Drawbacks of Traditional Materials

1. Steel

Corrosion: Steel is really prone to rust, especially in coastal and humid areas like the UAE. This corrosion can weaken structures and lead to constant repairs.

Weight: It’s quite heavy, which drives up transportation and installation costs.

Maintenance: It needs regular painting, coating, and inspections to stay in good shape.

2. Concrete

Cracking: Concrete can easily crack due to thermal expansion, shrinkage, or chemical reactions.

Steel Reinforcement Issues: The steel rebar within concrete can corrode, causing spalling and shortening its lifespan.

Environmental Impact: The production of cement has a significant carbon footprint.

3. Timber

Decay: Timber is vulnerable to rot, termites, and the effects of weather.

Fire Hazard: It’s flammable, which can create safety concerns.

Limited Lifespan: In harsh environments, timber often needs to be replaced frequently.

Why GFRP Outshines Traditional Materials

1. Corrosion Resistance

GFRP stands out because it doesn’t rust, rot, or corrode, even when faced with saltwater, harsh chemicals, or extreme weather conditions. This makes it a perfect choice for coastal infrastructure, water treatment facilities, and bridges in the tough environment of the UAE.

2. Lightweight Yet Strong

One of the best things about GFRP is that it’s much lighter than steel or concrete, yet it still provides comparable, if not better, tensile strength. This not only cuts down on transportation costs but also makes installation easier and opens the door to creative architectural designs.

3. Low Maintenance

When it comes to upkeep, GFRP structures are a breeze. Unlike steel or timber, they don’t need regular painting or anti-corrosion treatments, which can lead to significant savings over time.

4. Design Flexibility

GFRP can be shaped into just about any form or size, making it ideal for tailored solutions in architectural facades, domes, screens, and beyond.

5. Sustainability

Lower Carbon Footprint: The process of making GFRP results in fewer emissions compared to traditional materials like steel or concrete.

Recyclability: When GFRP reaches the end of its life, it can be recycled, aligning with green building standards.

Energy Efficiency: Thanks to its thermal properties, GFRP helps keep indoor temperatures stable, which can lower energy consumption.

GFRP in Action: UAE’s Infrastructure Revolution

The UAE is experiencing a remarkable rise in the demand for GFRP, with projections estimating the market will hit $182.3 million by 2028. This impressive growth is driven by several key factors:

– Major infrastructure projects that require cutting-edge materials.

– Government initiatives that champion sustainability and innovation.

– The tough desert and coastal conditions that put traditional materials to the test.

GFRP rebars are increasingly being used as alternatives to steel for reinforcing concrete, particularly in bridges, roads, and marine structures. Other uses include:

– Weather-resistant enclosures and kiosks for utilities

– Architectural cladding and decorative features

– Ladders, safety cages, and handrail systems

– Gratings, cable trays, and manhole covers

The Role of GFRP Manufacturing Companies in UAE

In the UAE, a GFRP manufacturing company is more than just a supplier; they’re a partner in innovation. These companies provide:

– Custom design and fabrication tailored to specific project needs

– Technical know-how in composite engineering

– Local manufacturing for quicker turnaround times and responsive support

– Adherence to international standards for quality and safety

Among the top players in this field are GRP Industries and Fiberzone LLC, both boasting decades of experience in sectors like power, water, oil & gas, and construction.

Comparing GFRP with Traditional Materials

| Feature | GFRP | Steel | Concrete | Timber |

| Corrosion Resistance | Excellent | Poor | Moderate | Poor |

| Weight | Lightweight | Heavy | Heavy | Moderate |

| Maintenance | Low | High | Moderate | High |

| Design Flexibility | High | Moderate | Low | Moderate |

| Sustainability | High | Low | Low | Moderate |

| Cost Over Lifecycle | Low | High | Moderate | High |

| Fire Resistance | Good | Excellent | Excellent | Poor |

| Recyclability | Yes | Yes | Limited | Yes |

Case Studies: GFRP Transforming UAE Projects

1. Bridges and Marine Structures

GFRP rebars are making waves in the construction of bridges and piers, providing incredible durability against saltwater corrosion and cutting down on maintenance needs.

2. High-Rise Buildings

With GFRP panels and enclosures, modern skyscrapers are getting a boost. These lightweight and strong materials not only look great but also enhance energy efficiency and longevity.

3. Utility Infrastructure

In the harsh UAE climate, weatherproof GFRP enclosures are a game changer, safeguarding sensitive electrical and water equipment to ensure reliable service and safety.

Sustainability: Building a Greener UAE

The UAE is all in on sustainability, and GFRP is leading the charge. Thanks to its lower environmental impact, recyclability, and energy saving features, GFRP fits perfectly with the nation’s green building codes and vision for a sustainable future.

Choosing the Right GFRP Manufacturing Company in UAE

When you’re on the hunt for a GFRP manufacturing company in the UAE, keep these points in mind:

Experience and Reputation: Seek out established manufacturers known for delivering top-notch GFRP products.

Customization Capabilities: It’s essential to find a company that can tailor solutions to meet your project’s specific needs.

Technical Support: Having access to engineering expertise and after-sales service can make all the difference in ensuring your project runs smoothly.

Compliance: Make sure the company adheres to international quality and safety standards.

The Future: Why GFRP Is Here to Stay

The construction industry is at a pivotal moment. As urbanization speeds up and sustainability becomes a must, GFRP is stepping up as the go to material for future-ready infrastructure. Its unbeatable mix of durability, efficiency, and environmental responsibility makes it a cornerstone for the UAE’s upcoming projects.

Conclusion

The transition from traditional materials to GFRP isn’t just a passing fad it’s a game changer. For those shaping the future of the UAE, the message couldn’t be clearer: GFRP provides the performance, flexibility, and sustainability necessary to tackle the challenges of tomorrow. By selecting the right GFRP manufacturing company in the UAE, you’re not just ensuring your infrastructure is built to endure; you’re also paving the way for leadership in innovation.

Teaming up with a top GFRP manufacturing company in the UAE opens up exciting opportunities for architects, engineers, and developers creating projects that can withstand the test of time, climate, and innovation.