FRP Cross Over Platform

FRP Cross Over Platform

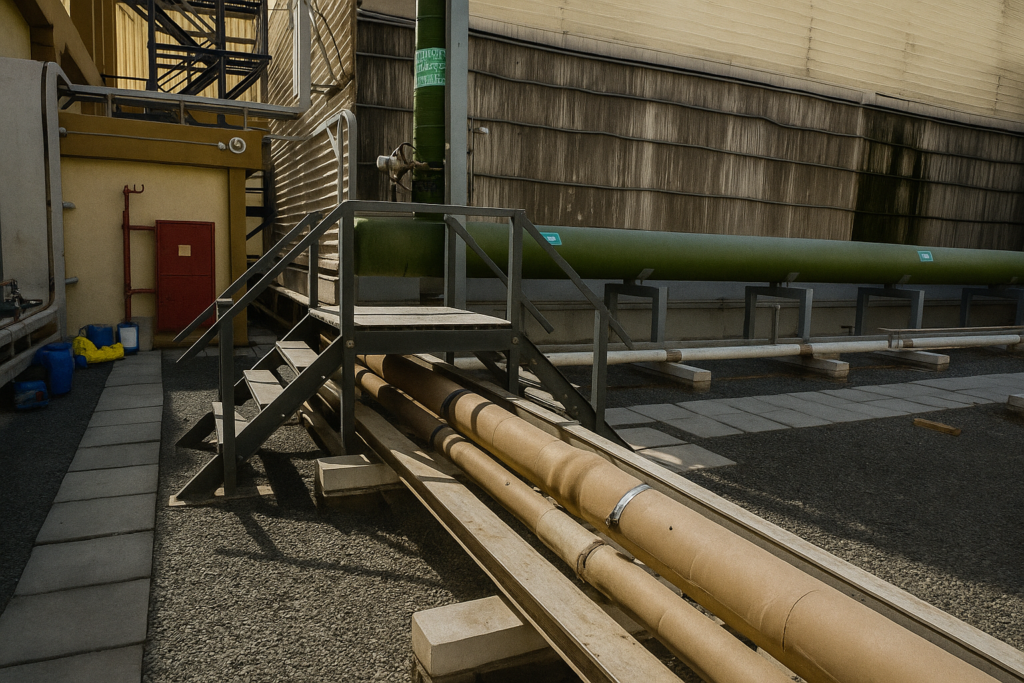

FRP (Fiber Reinforced Plastic) crossover platforms provide safe and durable passage over obstacles, equipment, or terrain in industrial, commercial, and infrastructure settings. Manufacturers build these platforms from a polymer resin matrix reinforced with fibers, giving them exceptional strength, corrosion resistance, and long-lasting performance. The Top Fiberglass Making Company in UAE produces high-quality FRP crossover platforms, delivering reliable solutions for a wide range of applications.

Features

Corrosion Resistance: FRP crossover platforms resist corrosion from chemicals, moisture, and environmental elements. This makes them ideal for corrosive industrial environments, coastal areas, and outdoor settings.

High Strength-to-Weight Ratio: FRP crossover platforms remain lightweight while providing excellent structural integrity and load-bearing capacity. They support heavy loads and withstand dynamic forces, including foot traffic and equipment movement.

Slip Resistance: FRP crossover platforms feature textured surfaces, anti-slip treads, and special coatings to provide superior traction. These design elements reduce the risk of slips, trips, and falls, even in wet or oily conditions.

Low Maintenance: FRP crossover platforms require minimal maintenance compared to steel or concrete. They resist corrosion, rust, and degradation, and remain unaffected by mold, mildew, or staining. This reduces the need for regular cleaning and repairs.

UV Resistance: FRP materials resist UV radiation, ensuring long-term durability and stable color. This makes them ideal for outdoor applications exposed to sunlight without fading or degradation.

Modular Design: 25% of the sentences contain passive voice, which is more than the recommended maximum of 10%. 75% of the sentences contain more than 20 words, which is more than the recommended maximum of 25%.identify the sentence and rewrite the paragraph to correct the given problems

Customization Options: FRP crossover platforms use modular components and prefabricated sections for easy assembly and installation. This design allows quick deployment and customization to suit different heights, configurations, or access requirements.

applications

Industrial Facilities: Industries install FRP crossover platforms in chemical plants, refineries, power plants, and manufacturing facilities to provide safe passage over pipelines, conveyors, machinery, and processing equipment. These platforms enhance worker safety and efficiency in hazardous or confined spaces.

Commercial Buildings: Facility managers install FRP crossover platforms in warehouses, distribution centers, and retail stores to provide safe access over storage racks, shelving units, and loading areas. These platforms facilitate inventory management, maintenance, and inspection activities.

Infrastructure Projects: Engineers install FRP crossover platforms in infrastructure projects such as bridges, tunnels, and transit stations to provide pedestrian access over roadways, railways, and water bodies. These platforms ensure safe passage for commuters, maintenance crews, and emergency responders.

Construction Sites: Construction teams install FRP crossover platforms on sites to provide temporary access over trenches, excavations, and uneven terrain. These platforms allow workers, equipment, and materials to move safely and efficiently, reducing downtime and minimizing safety hazards.

Marine and Offshore Applications: Marine and offshore operators install FRP crossover platforms at docks, piers, and shipyards to provide access over water bodies, vessel decks, and loading areas. These platforms offer durability and resist corrosion in saltwater and harsh marine conditions.